Over the last two years, we’ve all learned to pivot, make changes on the spot, adapt to our “new normal.” While we couldn’t plan for an unprecedented, global pandemic and its compounding aftershocks, planning for the changes we can anticipate and control is essential because—like it or not—change is inevitable. Managing the use of COTS components in critical applications is a big task, especially when it comes to saving time and cost, while minimizing risk to performance and program disruption. It is serious business.

Over the last two years, we’ve all learned to pivot, make changes on the spot, adapt to our “new normal.” While we couldn’t plan for an unprecedented, global pandemic and its compounding aftershocks, planning for the changes we can anticipate and control is essential because—like it or not—change is inevitable. Managing the use of COTS components in critical applications is a big task, especially when it comes to saving time and cost, while minimizing risk to performance and program disruption. It is serious business.

What is configuration management?

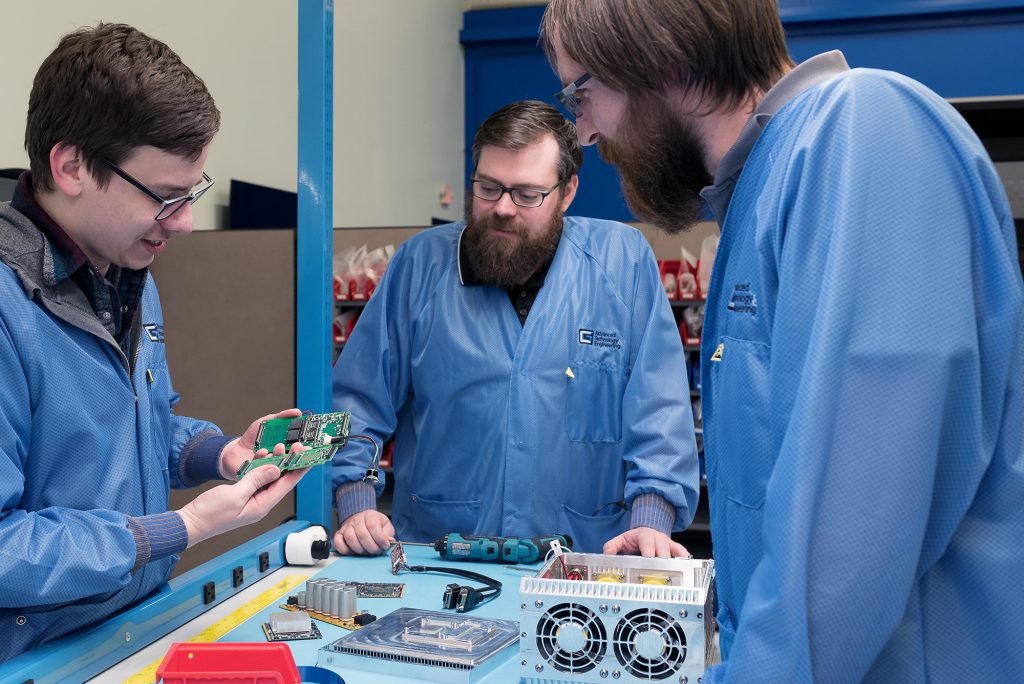

At Crystal Group, configuration management involves forward-looking measures to extend the life of your rugged compute solution. This is a systematic approach to track and factor in hardware changes to replace end-of-life and last-time-buy components over the operational life of your product or system.

It is important to note that configuration management cannot be applied to every hardware or software element of every product, so you must be selective and start with stable technologies that have a lot of procurement runway when architecting a solution.

For example, starting at the design phase of a project, our engineers work to incorporate open and stable architectures, standard interfaces, and long-life chipsets and processors into the design to create a robust, yet flexible compute solution. This is especially critical today, as the supply chain can dictate component availability.

Why does configuration management matter?

Configuration management saves your program schedule and cost, while minimizing risk and disruption. Key elements to our proactive configuration management program includes:

- Proactively collaborating with our suppliers, strategic partners, and customers

- Selecting long-life COTS components that can be ruggedized from top suppliers

- Providing design alternatives, creating technology insights, and proactively charting roadmap options for improved operational readiness

- Ensuring standards compliance

- Ensuring products conform to functional and physical requirements of the approved design

- Maintaining detailed action records

- Facilitating smooth transitions while minimizing risks and disruptions

- Preventing costly and unnecessary recertifications

- Planning technology insertions before sources of supply diminish

These forward-looking measures ensure changes to the original configuration are seamless while maintaining consistent product integrity, performance, and compliance.