About one year ago, we expanded our engineering department by adding the Advanced Program Pursuits (APP) team. This team is primarily responsible for the design and development of prototypes with unique requirements and short timelines.

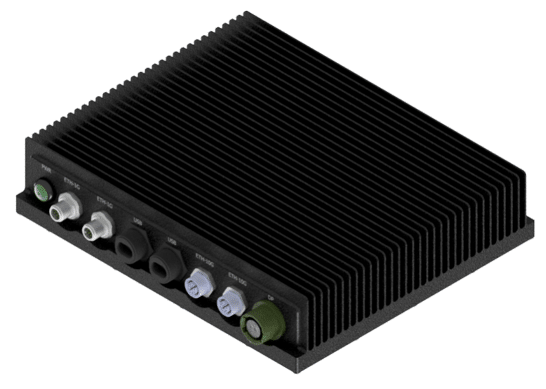

The first project that the APP team took on was the RE3500, a rugged small form factor designed to create operator situational awareness. Due to the completely unique nature of this hardware, our engineers were given hardly any requirements for the design other than it needed to be small, had to incorporate a next-generation embedded GPU, and must be completed in six months.

Not only was the actual design and build of the RE3500 a challenge, but our brand-new team of engineers had to quickly figure out how to work together and establish our rapid prototyping process. By communicating constantly with the customer, we were able to design the exact solution they needed and glean better insights into the requirements that were important to them.

After accepting this project, we quickly determined that the RE3500 would be operating in an amphibious environment and would need to be sealed. So, we developed a custom-machined chassis in our in-house CNC shop. This custom chassis was needed to meet the size requirements, keep water out, and prevent shock when it was deployed in areas where it could be exposed to water.

The RE3500 also had to process large amounts of data when deployed in the field for applications where image segmentation or object detection is needed. Additionally, an optimized I/O was required to ensure that signals processing in these applications would be reliable.

By using in-house resources, like our CNC shop and MIL-STD testing labs, we were able to deliver a custom prototype to the customer by their six-month deadline. Now, the RE3500 is being integrated into its shipboard application successfully.